- SINCE 2009

- Dubai Investment Park 02

- +971 4 824 0002

- [email protected]

Shed 06, Aber Warehouse

Dubai Investment Park 02,

PO Box: 414345 , Dubai.

United Arab Emirates.

Mobile: +971 50 2420957

Email: [email protected]

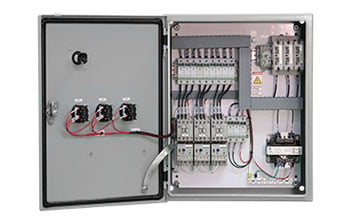

A motor control panel, also known as a motor control center or MCC, is a device used to control the operation of motors in industrial and commercial applications. It typically includes switches, breakers, and other components that allow the operator to start, stop, and control the speed of motors. Motor control panels are used in a wide range of industries, including manufacturing, mining, oil and gas, and power generation, to control the operation of motors that power machinery and equipment.

Motor control panels can control a single motor or a group of engines. They typically consist of a metal enclosure that contains various electrical components, such as circuit breakers, fuses, and contractors, which are used to control the flow of electrical power to the motor. The panel may also include indicators, such as lights or gauges, to display the engine’s status or the board itself.

In addition to controlling the operation of motors, motor control panels can also protect against electrical hazards, such as overloading and short circuits. They may be equipped with safety features such as ground fault circuit interrupters (GFCIs) and overload protection to help prevent electrical shocks and damage to the motor or other equipment.If you want more electrical service, Go through Switchgear solutions is the best choise for you.

Motor control panels are typically larger than standard electrical panels and contain specialized components such as motor starters, overload protection devices, and circuit breakers. These panels also usually include a control system that allows operators to start and stop the motors, adjust their speed, and monitor their performance. In general, motor control panels are essential for ensuring electrical motors’ safe and efficient operation in commercial and industrial settings.

A motor control panel is a piece of electrical equipment that houses the components used to control and power electric motors in a central location. It typically includes a main breaker, control circuits, and engine and other electrical systems protection devices.

There are several motor control panels, including manual motor control panels, programmable motor control panels, and intelligent motor control panels.

The components of a motor control panel may include a main breaker, contactors, overload relays, fuses, control transformers, and push buttons.

A motor control panel receives electrical power from a source and uses various components to control the flow of electricity to an electric motor. The board may include switches or controls to start, stop, and regulate the engine’s speed.

A motor control panel in industrial settings offers streamlined operation and enhanced safety. It centralizes control over motors, ensuring efficient performance and quick response to changes. These panels simplify maintenance, reducing downtime. With features like overload protection and fault detection, they enhance equipment longevity. Overall, motor control panels contribute to improved productivity, safety compliance, and operational reliability in industrial environments.

A motor control panel should have features such as overload protection, motor starters, fault diagnostics, and remote monitoring capabilities. These elements ensure efficient motor operation by preventing damage from overloads, enabling precise control, facilitating quick fault identification, and allowing remote supervision for proactive maintenance and troubleshooting. An effective motor control panel streamlines operations, enhances safety, and contributes to the longevity and reliability of the motorized systems it governs.

Our team of specialists from varying disciplines will guarantee the provision of integrated solutions to finish your task by drawing on their experience from the collection of our completed projects.

VOLTRONIX

Shed 06, Aber Warehouse

Dubai Investment Park 02,

PO Box: 414345 , Dubai.

United Arab Emirates.

Landline: +971 4 8240002

Mobile: +971 50 2420957

Email: [email protected]